Description

Compared with other transmissions, the rack and pinion have the following advantages: the instantaneous transmission ratio of the two wheels is constant, and the motion transmission is accurate and reliable. It can realize the information of parallel, rubber, and staggered shafts. The circumferential speed and power used range are comprehensive, and the transmission efficiency is high, generally 0.94-0.99. The service life is long, the structure is compact, and the maintenance is simple.

Compared with other transmissions, gear transmission has the following disadvantages: higher requirements for gear manufacturing and installation accuracy and higher cost. It is not suitable for information at a considerable distance from the shaft.

Gear transmission is used to transmit the movement between two axes in the machine. According to the relative position between the two axes and the tooth direction of the gear teeth, the gear transmission can be divided into three types: parallel shaft gear transmission, intersecting shaft gear transmission, and staggered shaft gear.

Description

| Model Number | M1,M1.5,M2,M2.5,M3,M4,M5,M8,M12 and etc. |

| Material | Brass, C45 steel, Stainless steel, Copper, POM, Aluminum, Alloy, and so on |

| Surface treatment | Zinc-plated, Nickel plated, Passivation, Oxidation, Anodization, Geomet, Dacromet, Black Oxide, Phosphatizing, Powder Coating, and Electrophoresis. |

| Standard | ISO, DIN, ANSI, JIS, BS and Non-standard. |

| Precision | DIN6,DIN7,DIN8,DIN9. |

| Teeth treatment | Hardened, Milled, or Ground |

| Tolerance | 0.001mm-0.01mm-0.1mm |

| Finish | shot/sandblast, heat treatment, annealing, tempering, polishing, anodizing, zinc-plated |

| Items packing | Plastic bag+Cartons Or Wooden Packing |

| Payment terms | T/T, L/C |

| Production lead time | 20 business days for sample,25 days for the bulk |

| Samples | Sample price range from $2 to $100. sample express request paid by clients |

| Application | 1. Automatic controlling machine 2. Semi-conductor industry 3. General industry machinery 4. Medical equipment 5. Solar energy equipment 6. Machine tool 7. Parking system 8. High-speed rail and aviation transportation equipment, etc. |

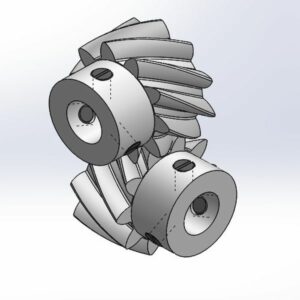

The intersecting shaft gear transmission is divided into straight tooth bevel gear transmission and curved tooth bevel gear transmission.

The straight tooth bevel gear transmission intersects two peripheral lines, the shaft cross angle is 90°, it is widely used, easy to manufacture and install, the information is poor in stability, the bearing capacity is low, the axial force is significant, and it is used for the operation with low speed (<5m / s =, small load and stable operation)

The curved tooth bevel gear transmission has a large intersection and coincidence between the two shafts, stable operation, high bearing capacity, sizeable axial force, and gear direction. It is used for transmission with high speed and heavy loads.

Staggered shaft helical gear transmission divided staggered shaft gear transmission and worm drive.

The staggered shaft helical gear transmission has two axes staggered, and the two gears are in point contact. The transmission efficiency is low, suitable for communication with low load and low speed.

The two axes of the worm drive are staggered. Generally, 90° and the transmission is relatively large. Generally i = 10-80. The structure is compact, the information is stable, the noise and vibration are slight, the transmission efficiency is low, and it is easy to generate heat.

Gear Transmission Maintenance

Proper maintenance is the necessary condition for extending the service life of gears for ordinary working of intelligent gear transmissions. The daily maintenance mainly includes the following contents:

1. Installation and running-in. The fixing and positioning of the gears should meet the technical requirements during installation gears. Using a pair of new gears to run in first, that is, under no-load and step-by-step loading, run for more than ten hours to dozens of hours. Then clean the box and replace it with new oil before use.

2. Proper use of gear transmission, start-up, loading, unloading, and gear shifting, should strive to be stable to avoid impact loads and Party B is causing teeth were broken and other failures.

3. Frequently check the condition of the lubrication system, such as the amount of lubricating oil, the state of oil supply, the quality of the lubricating oil, etc., to avoid the occurrence of impact loads, and regularly replace and supplement the lubricating oil of specified brand according to the user’s specifications.

4. Monitor the operating status, and watch, touch, and hear for abnormal sounds if the cargo box is overheated, and “work with fault” is prohibited. For gear transmission at high speed, heavy loads, or on essential occasions, an automatic detection device can be adopted to ensure the safety and reliability of gear transmission.

5. Install the protective cover. For open gear transmission, the protective cover should be installed to prevent dust, chips, and other debris from entering the tooth surface, accelerating the wear of the tooth surface, and protecting personal safety.