Product Description

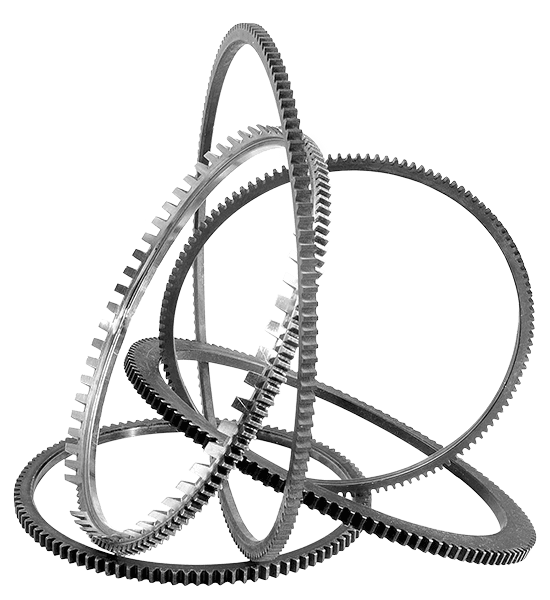

OEM Precision Small Nylon Plastic Internal Ring Chain Gear for Toy

Products Type

We can custom shape,size,color material and quantity for plastic gear as your requirment.

Products Specification

1. Various hardness for your choice.

2. Good abrasion, heat and oil resistance.

3. Good anti-aging performance and gas tightness.

4. Ease of bonding to other material.

5. Excellent oxygen and CHINAMFG resistance.

6. Non-flammable,self-extinguish.

| Material | PA,PA6,PA66,PP,PE,LDPE,HDPE,UWHDPE,PTFE,POM,ABS,or Custom Compound (Any custom compound plastic is available) |

| Size | According to samples or drawings |

| Color | Black,white,red,green,transparent or any color according to Pantone colors |

| Finish | High Gloss,Fine Grain,Electroplating,Painting,Printing,Texture etc,or as request |

| Type | Round,square,rectangular,or any nonstandard shape as request |

| Logo | Debossed,embossed,printed logo or as request |

Plastic Material Properties

Company Profile

Zhongde (ZheJiang ) Machinery Equipment Co.,LTD is a company integrated in design,OEM&ODM plastic&rubber&CNCparts production.We can provide the best products and service at a competitive price.

Main Products

We can provide OEM service,which means producing base on your drawings or samples,also we can design according to its application or customer`s requirments.

Order Operation Flow

We execute each step according to the operation process flow, strictly, seriously and meet the requirements of customers with good quality on time.

For Fast Quotation,Please Inform Below Details

1. Production type

2. Material specification (or let us know the using environmental)

3. Size details? (or provide drawings or samples for refference)

4. Quantity request

5. Prefer color /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | Order Sample For sample price, package information, and logisti

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do ring gears contribute to power transmission?

Ring gears play a significant role in power transmission within mechanical systems. Here’s a detailed explanation of how ring gears contribute to power transmission:

- Torque Transfer: Ring gears are designed with teeth on their outer or inner circumference, depending on whether they are external or internal ring gears. These teeth mesh with the teeth of other gears, such as pinion gears or planetary gears. As the driving gear rotates, the meshing teeth engage with the ring gear’s teeth, transmitting torque from the driving gear to the ring gear. This torque transfer enables the ring gear to rotate and transmit power to other components or systems connected to it.

- Rotational Motion: Ring gears convert the rotational motion of the driving gear into rotational motion of the ring gear itself. The teeth on the ring gear provide a positive engagement with the teeth of the driving gear, ensuring a synchronized rotation. As the driving gear rotates, the meshing teeth push against the ring gear’s teeth, causing it to rotate in the same direction and at a proportional speed determined by the gear ratio. This rotational motion is crucial for transmitting power to different parts of the system or driving various mechanisms and components.

- Speed Reduction or Increase: Ring gears, in conjunction with other gears in the system, can be used to achieve speed reduction or increase. By varying the sizes of the driving gear, the ring gear, and other intermediate gears, different gear ratios can be achieved. When the driving gear is smaller than the ring gear, the ring gear rotates at a slower speed than the driving gear, resulting in speed reduction. Conversely, if the driving gear is larger, the ring gear rotates at a faster speed, leading to speed increase. This ability to control gear ratios allows for power transmission at desired speeds and enables systems to meet specific operational requirements.

- Load Distribution: Ring gears distribute the transmitted loads across their circumference. The teeth of the ring gear engage with multiple teeth of other gears, ensuring that the load is shared among these meshing points. This load distribution helps prevent localized stress concentrations and excessive wear on specific gear teeth. By distributing the load, ring gears contribute to the overall durability and longevity of the gear system, allowing for reliable power transmission even under demanding conditions.

- Compact and Efficient Design: Ring gears offer a compact and efficient design for power transmission. Their annular shape allows for a high gear ratio within a small space, making them ideal for applications where space is limited. Additionally, ring gears can be integrated into various gear configurations, such as planetary gear systems or gearboxes, which further enhance their power transmission capabilities. This compact and efficient design contributes to overall system efficiency and performance.

Overall, ring gears are essential components in power transmission systems. Through torque transfer, rotational motion, speed control, load distribution, and their compact design, ring gears enable efficient and reliable power transmission in a wide range of mechanical applications.

How do you prevent backlash and gear play in a ring gear mechanism?

Preventing backlash and gear play in a ring gear mechanism is crucial for ensuring accurate and precise operation. Here’s a detailed explanation of how to prevent backlash and gear play in a ring gear mechanism:

- Precise Gear Design: The design of the ring gear and associated gears should be carefully engineered to minimize backlash. This involves selecting appropriate tooth profiles and gear geometry that promote proper meshing and minimize clearance between the gear teeth. The gear design should consider factors such as tooth thickness, pressure angle, and tooth contact ratio to achieve optimal gear meshing without excessive play.

- Tight Manufacturing Tolerances: Close manufacturing tolerances are essential to reduce backlash in a ring gear mechanism. The gear components, including the ring gear and mating gears, should be produced with high precision to ensure accurate tooth dimensions and minimize any gaps or play between the gear teeth. Tight manufacturing tolerances help achieve a tighter meshing fit, reducing backlash and gear play.

- Proper Gear Alignment: Accurate alignment of the ring gear and mating gears is crucial for minimizing backlash. The gears should be properly aligned along their axes to ensure precise engagement and minimize any misalignment that can contribute to play. Adequate alignment can be achieved through careful assembly techniques, such as using alignment fixtures, proper shimming, and precision measurement tools.

- Preload or Pre-tension: Applying preload or pre-tension to the ring gear mechanism can help reduce backlash and gear play. Preload involves applying a slight compressive force or tension to eliminate any clearance or gaps between the gear teeth during operation. This can be achieved through various methods, such as using spring-loaded components, adjustable shims, or axial preloading devices.

- Optimized Lubrication: Proper lubrication is essential for reducing friction and minimizing gear play. Lubricants with appropriate viscosity and film strength should be used to ensure smooth gear operation and reduce any unwanted movement or play between the gear teeth. Regular lubricant maintenance, such as monitoring oil levels and replenishing or replacing lubricants as needed, helps maintain optimal lubrication conditions and minimize backlash.

- Mechanical Backlash Compensation: In some applications, mechanical compensation mechanisms can be employed to actively compensate for any residual backlash. These mechanisms can include systems with adjustable clearances, anti-backlash devices, or dual-gear arrangements that counteract the effects of backlash. Mechanical backlash compensation techniques can help maintain precise positioning and eliminate any undesired play in the gear mechanism.

By implementing these measures, it is possible to significantly reduce or eliminate backlash and gear play in a ring gear mechanism. Careful gear design, tight manufacturing tolerances, proper alignment, preload or pre-tension, optimized lubrication, and mechanical compensation techniques all play a role in ensuring accurate and precise operation of the ring gear mechanism.

Can you explain the concept of meshing with a ring gear?

Meshing with a ring gear refers to the process of engaging and interlocking the teeth of a gear with the internal teeth of a ring gear. It is a fundamental concept in gear systems where the rotation and torque transfer occur between two gears. Here’s a detailed explanation of the concept of meshing with a ring gear:

When two gears come into contact and their teeth interlock, they are said to be meshing. In the case of a ring gear, the meshing occurs when the teeth of an external gear, such as a pinion gear, engage with the internal teeth of the ring gear. The teeth of the pinion gear fit precisely between the teeth of the ring gear, creating a mechanical connection.

The process of meshing involves several important considerations:

- Tooth Engagement: Proper tooth engagement is crucial for efficient and smooth meshing. The teeth of the gears must align correctly to ensure a proper fit. This alignment ensures that the teeth make contact at the correct pitch point and maintain a consistent mesh throughout the gear rotation.

- Tooth Profile: The tooth profile, such as the shape and size of the teeth, is designed to facilitate smooth meshing. The profile ensures that the teeth slide smoothly against each other without excessive friction, noise, or wear. The tooth profile also affects the load distribution, torque transmission, and overall performance of the gear system.

- Lubrication: Lubrication plays a crucial role in the meshing process. It helps reduce friction and wear between the teeth, ensuring smooth operation and preventing damage to the gears. Proper lubrication also helps dissipate heat generated during meshing, improving the overall efficiency and reliability of the gear system.

- Clearance and Backlash: Clearance and backlash are important considerations in gear meshing. Clearance refers to the space between the tips of the teeth of the external gear and the root of the teeth of the ring gear. Backlash is the amount of play or movement between the engaged teeth. Proper clearance and backlash are necessary to prevent interference, ensure smooth rotation, and accommodate any misalignment or thermal expansion that may occur during operation.

The quality of the meshing directly affects the performance, efficiency, and reliability of the gear system. Proper design, manufacturing precision, and maintenance practices are essential to achieve optimal meshing between gears, including ring gears.

It’s important to note that the specific parameters and requirements for meshing, such as tooth geometry, clearance, backlash, and lubrication, may vary depending on the application, gear type, and operating conditions.

editor by Dream 2024-04-26