Product Description

Product information

Product material: HT200

Suitable for: mechanical lathes

Product introduction: the advantages of pulley drive: pulley drive can ease the impact of load; Pulley drive running smoothly, low noise, low vibration; The structure of the pulley drive is simple and easy to adjust. Pulley transmission for pulley manufacturing and installation accuracy is not as strict as meshing transmission; The pulley transmission has the function of overload protection; The adjustment range of center distance between 2 shafts of pulley transmission is large. The disadvantages of belt drive are: pulley drive elastic sliding and skid, low transmission efficiency and can not maintain accurate transmission ratio; When the pulley transmission transmits the same large circumferential force, the contour size and the pressure on the shaft are larger than that of the meshing transmission. Pulley drive belt has shorter life

Product name: pulley

Type size: various models (can be customized)

Material: cast iron/cast steel /(can be customized)

Standard type: national standard

Applicable machine: CNC lathe

Pulley:

Pulley, belongs to the wheel hub class parts, generally relative size is relatively large, the manufacturing process is generally cast, forging. The general size of the larger design for the casting method, the material is generally cast iron (casting performance is good), rarely cast steel (steel casting performance is not good); Generally small size, can be designed for forging, the material is steel

The basic information

Chinese name

pulley

Foreign names

pulley

Application field

mechanical

role

Transmit power

Production requirements

Pulley material and production requirements

1. The belt pulley used for the ventilator is made of grey cast iron HT200,HT250, etc. (but steel, copper, aluminum, etc., can also be used according to customer requirements).

2. The pulley should meet: light weight, uniform mass distribution, eliminate the internal stress produced in the manufacturing, pulley should be static balance correction.

The belt specification

The specifications of the triangle belt are divided by the size of the back width (top width) and the height (thick). According to the different size of the back width (top width) and the height (thick), the national standard provides the O, A, B, C, D, E and other models of the triangle belt. The section width, top width and height of each type of the triangle belt are not the same. So the pulley must be made according to the shape of the triangle belt a variety of groove; These different slots. It determines the pulley O pulley, A pulley, B pulley, C pulley, D pulley, E pulley and other types of pulley.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type B |

| Manufacturing Process: | Casting |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

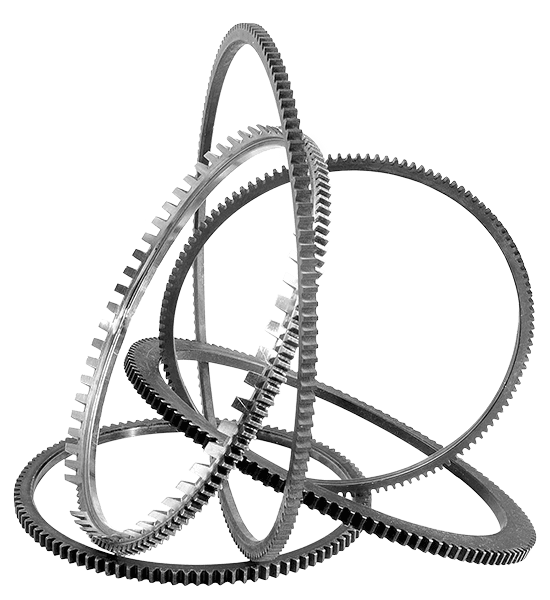

What are the benefits of using a ring gear mechanism?

A ring gear mechanism, also known as an annular gear mechanism, offers several benefits in various applications. Here’s a detailed explanation of the advantages of using a ring gear mechanism:

- Compact Design: Ring gears provide a compact design solution due to their annular shape. They can be integrated into tight spaces and offer a high gear ratio within a small footprint. This compactness is particularly advantageous in applications where space is limited or where lightweight and streamlined designs are required.

- Efficient Power Transmission: Ring gears facilitate efficient power transmission. The meshing of the gear teeth ensures a reliable transfer of torque and rotational motion. This efficiency is crucial in applications that require the smooth and precise transmission of power, such as automotive transmissions, industrial machinery, and robotics.

- Load Distribution: The circular shape of the ring gear allows for uniform load distribution across its circumference. This helps distribute the transmitted forces and reduces localized stress concentrations. As a result, ring gears can handle higher loads and provide improved durability and longevity compared to other gear mechanisms.

- Multiple Meshing Points: Ring gears typically have multiple meshing points with other gears, such as pinion gears or planetary gears. This distributed meshing enables efficient load sharing and helps distribute the torque across multiple points, reducing wear and enhancing the overall gear system’s performance and reliability.

- Versatile Applications: Ring gears find wide application across various industries and systems, including automotive, aerospace, industrial machinery, robotics, power generation, and more. Their versatility stems from the ability to configure ring gears in different types, such as external, internal, helical, or bevel, to suit specific application requirements.

- Precision and Smooth Operation: Ring gears provide precise and smooth operation due to the continuous contact between the gear teeth during rotation. This results in reduced noise, vibration, and backlash, making ring gears suitable for applications where precise motion control, quiet operation, and high positional accuracy are critical.

- Redundancy and Fault Tolerance: In certain applications, such as gearboxes, the ring gear mechanism can offer redundancy and fault tolerance. If one gear or gear stage fails, the remaining gears can continue to transmit power, allowing the system to operate partially or with reduced performance until maintenance or repair can be performed.

The benefits of using a ring gear mechanism make it a preferred choice in many mechanical systems where compactness, efficient power transmission, load distribution, and precision are essential. By leveraging these advantages, engineers and designers can achieve improved performance, reliability, and overall system efficiency in their applications.

How does a ring gear impact the overall efficiency of a system?

A ring gear plays a significant role in the overall efficiency of a system. Here’s a detailed explanation of how a ring gear impacts system efficiency:

- Power Transmission: Ring gears are responsible for transmitting power from one component to another within a system. They facilitate the transfer of rotational energy and torque between gears, shafts, or other drivetrain elements. The design and quality of the ring gear, along with its meshing with other gears, directly affect the efficiency of power transmission. Well-designed and properly maintained ring gears minimize energy losses due to friction, misalignment, or backlash, resulting in higher overall system efficiency.

- Friction and Wear: The interaction between the ring gear and other gears or components introduces friction, which can lead to energy losses and reduced efficiency. The smoothness of the gear surfaces, the quality of the lubrication, and the design of the gear teeth profile all influence the amount of friction generated. High-quality ring gears with proper lubrication and optimized tooth profiles can minimize friction and wear, thereby improving system efficiency by reducing energy losses.

- Mechanical Losses: In any gear system, there are inherent mechanical losses due to factors such as gear meshing, rolling resistance, and internal friction. These losses can impact the overall efficiency of the system. The design and quality of the ring gear, including factors such as gear tooth geometry, material selection, and surface finish, can help minimize mechanical losses. By reducing these losses, the ring gear contributes to improved system efficiency.

- Load Distribution: Ring gears play a critical role in distributing loads within a system. They help evenly distribute the forces and torque applied to the gear system, preventing localized overloading and reducing the risk of premature component failure. Proper load distribution achieved through well-designed ring gears ensures balanced operation, minimizes stress concentrations, and optimizes the system’s overall efficiency.

- Backlash and Precision: Backlash refers to the play or clearance between the gear teeth when they change direction. Excessive backlash can result in inefficient power transmission, reduced accuracy, and increased wear. Ring gears with tight tolerances and precise manufacturing help minimize backlash, ensuring smooth and efficient operation. By reducing backlash and maintaining precise gear meshing, the ring gear contributes to improved system efficiency and accuracy.

- System Integration and Compatibility: Ring gears must be properly integrated into the overall system design and be compatible with other components. The alignment, mounting, and proper engagement of the ring gear with other gears or components are crucial for efficient operation. Misalignment or compatibility issues can lead to increased friction, wear, and energy losses. A well-integrated ring gear that is compatible with the system’s requirements contributes to improved overall efficiency.

- Maintenance and Lubrication: Regular maintenance and proper lubrication of the ring gear are essential for maintaining efficiency. Adequate lubrication reduces friction, wear, and heat generation, promoting efficient power transmission. Regular inspections, lubricant analysis, and timely lubricant replenishment or replacement help ensure optimal performance and efficiency of the ring gear and the overall system.

Overall, the design, quality, maintenance, and proper integration of the ring gear within a system significantly impact its efficiency. Through minimizing friction, reducing mechanical losses, optimizing load distribution, and ensuring precise operation, a well-designed and properly maintained ring gear contributes to improved overall system efficiency.

Can you explain the concept of meshing with a ring gear?

Meshing with a ring gear refers to the process of engaging and interlocking the teeth of a gear with the internal teeth of a ring gear. It is a fundamental concept in gear systems where the rotation and torque transfer occur between two gears. Here’s a detailed explanation of the concept of meshing with a ring gear:

When two gears come into contact and their teeth interlock, they are said to be meshing. In the case of a ring gear, the meshing occurs when the teeth of an external gear, such as a pinion gear, engage with the internal teeth of the ring gear. The teeth of the pinion gear fit precisely between the teeth of the ring gear, creating a mechanical connection.

The process of meshing involves several important considerations:

- Tooth Engagement: Proper tooth engagement is crucial for efficient and smooth meshing. The teeth of the gears must align correctly to ensure a proper fit. This alignment ensures that the teeth make contact at the correct pitch point and maintain a consistent mesh throughout the gear rotation.

- Tooth Profile: The tooth profile, such as the shape and size of the teeth, is designed to facilitate smooth meshing. The profile ensures that the teeth slide smoothly against each other without excessive friction, noise, or wear. The tooth profile also affects the load distribution, torque transmission, and overall performance of the gear system.

- Lubrication: Lubrication plays a crucial role in the meshing process. It helps reduce friction and wear between the teeth, ensuring smooth operation and preventing damage to the gears. Proper lubrication also helps dissipate heat generated during meshing, improving the overall efficiency and reliability of the gear system.

- Clearance and Backlash: Clearance and backlash are important considerations in gear meshing. Clearance refers to the space between the tips of the teeth of the external gear and the root of the teeth of the ring gear. Backlash is the amount of play or movement between the engaged teeth. Proper clearance and backlash are necessary to prevent interference, ensure smooth rotation, and accommodate any misalignment or thermal expansion that may occur during operation.

The quality of the meshing directly affects the performance, efficiency, and reliability of the gear system. Proper design, manufacturing precision, and maintenance practices are essential to achieve optimal meshing between gears, including ring gears.

It’s important to note that the specific parameters and requirements for meshing, such as tooth geometry, clearance, backlash, and lubrication, may vary depending on the application, gear type, and operating conditions.

editor by CX 2024-04-17